Why should you choose Openbravo Advanced Warehouse Operations?

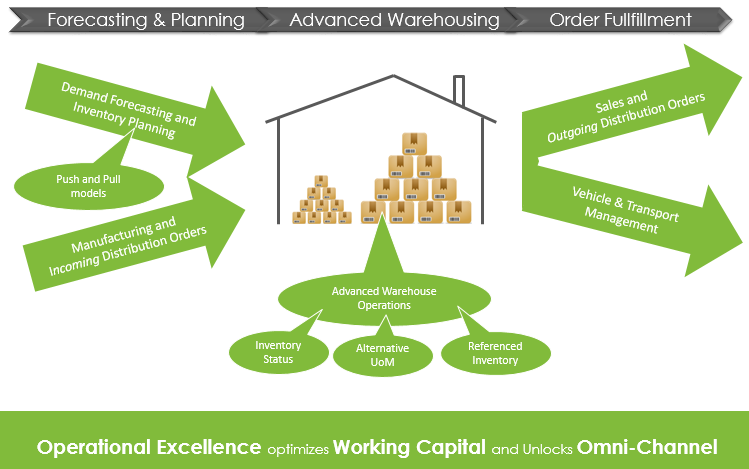

Advanced Warehouse Operations (AWO) is at the center of the new Openbravo Supply Chain Suite. It manages inventory once it is inside the warehouse and dynamically assigns bins or determines the most appropriate stock to be picked according to pre-configured set of rules or algorithms. It includes the multiple alternative Unit of Measure and Inventory Status functionalities while it very soon also will include the Referenced Inventory functionality.

Concerning the Supply Chain Suite, on the left of AWO we position Advanced Planning, with demand forecasting, inventory planning and Pull & Push methods. Also, here you find Distribution Order functionality to the existing methods for incoming goods. On the right of AWO we add the same Distribution Orders functionality but for outgoing goods while also here you find the Vehicle & Transport management module, which helps to organize the distribution with owned vehicles. For distribution with non-owned vehicles, Openbravo has integrations with several carriers.

The comprehensive set of Supply Chain functionalities on our Cloud-native software might already have made you decide to opt for Openbravo. If so, then please contact us! If that is not the case, read on.

At Openbravo we are very aware that software is nothing but a tool for you. And as with all tools, it should bring your organization more added value than it costs you. The bigger picture of Inventory Management, meaning from demand forecasting to advanced warehousing to optimized distribution is, from a finance perspective, all about working capital optimization: better inventory turns result in better cashflow and at the end of the days that’s what keeps the company, shareholders and employees happy. Of course that is correct, but you can’t say on a random Monday morning “let’s go and optimize our working capital!”. It doesn’t work like that.

From a sales/marketing perspective, proper inventory management eliminates one of the biggest impediments for omnichannel success. So, from this perspective it is critical success factor. Unfortunately, you can’t say on the same Monday morning “Let’s do a proper inventory management today and launch our omnichannel tomorrow!”. Many would wish it was that easy.

What should be done on the other hand, is approach this from an operational perspective, and more precisely by pursuing operational excellence in your organization. Because operational excellence is a key driver for working capital optimization and unlocks omnichannel success!

And here is where Openbravo Advanced Warehouse Operations – as center point of the Supply Chain Suite – comes into play: It is a set of multiple functionalities, each of them designed with a single purpose and cooperating in harmony: to optimize space utilization, to optimize staff utilization and/or to optimize stock utilization. It consists of:

- Intuitive and offline-resistant front-end user interface that allows operators to continue confirming tasks even when there is no connectivity.

- Intelligence for stock optimization; adaptive algorithms for picking, put-away and issuing. deviations for cross docking and inspection; self-replenishment, self-organizing, self-auditing features that continuously keeps the warehouse organized and correct;

- Intelligence for space optimization; chaotic/dynamic or static bin-system, or mixed; put-away with bin-capacities and dynamic occupation calculations; popularity codes for fast/slow movers; pickings geared to free bin-space or stock utilization;

- Intelligence for staff optimization; tasks presented by priority; internal and external routings; automatic label printing; travel sequence to avoid crisscrossing; on-the-fly front-end operations like receipts, picking, put-away, counts and look-ups;

- Warehouse operations cockpit for consolidated overview of all stock, tasks, reservations and transactions over multiple warehouses;

- Delta-management and decimals management; multiple alternative unit of measures;

- Scheduled tasks for wave/batched picking, self-organizing warehouse, self-replenishing warehouse and self-auditing warehouse;

- Blind receipts and other front-end configurations by routing, by user-role; rounding management for simple operation; configurable verbosity to identify warehouse bottlenecks.

To find out more about Openbravo Advanced Warehouse Operations, watch our webinar, How Retailers Optimize Inventory Management with Openbravo.

No Comment